Have you ever seen an experiment where flowers placed in liquid nitrogen are shattered? Most materials become more brittle and fragile as their temperature decreases. However, some metal alloys exhibit the opposite phenomenon, becoming stronger as the temperature decreases. Recently, a research team led by Professor Hyoung Seop Kim (GIFT, MSE) discovered the principle behind this phenomenon.

Equipment used in extreme environments such as spaceships and deep submergence vehicles requires special metals that can withstand cryogenic temperatures. Alloys made by combining several metal elements become stronger as the temperature decreases. It is known to be due to a specific atomic arrangement, face-centered cubic (FCC).

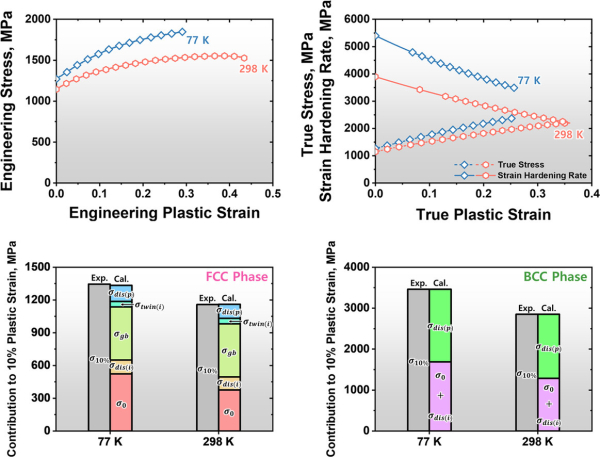

The team used Real-time Neutron Diffraction technology to analyze the interior of a metal alloy. As a result, they found that in an alloy composed of aluminum (Al), cobalt (Co), nickel (Ni), and vanadium (V), not only FCC structure but also body-centered cubic (BCC) structure affects the strength improvement at cryogenic temperatures.

While FCC increases strength as the atomic arrangement changes with decreasing temperature, BCC increases the strength of metal through the Peierls-Nabarro barrier, a force that hinders slipping. The team investigated that the slip resistance of BCC is sensitive to temperature and that temperature sensitivity works more effectively at cryogenic temperatures, making the metal stronger. Previously, FCC deformation was considered to play a key role on strengthening metals at extremely low temperatures, but this research revealed that the temperature dependence of BCC is much greater, contributing more to the strengthening of the alloy.

Prof. Kim stated, “We present an important insight for developing next-generation metal materials for extreme environments. It will be the basis for the space industry, such as Mars exploration and the construction of a lunar base, and for the new natural gas pipeline to be built in Alaska.” He added, “Adjusting the proportion of BCC structures will enable the design of custom alloys that perform optimally at various temperatures.”

This study was a collaborative effort involving Prof. Hyoung Seop Kim (GIFT, MSE), MSE Ph. D. candidate Gang Hee Gu, Prof. Yoon-Uk Heo, and Jungwook Cho (GIFT) alongside Dr. Stefanus Harjo, Wu Gong at Japan Proton Accelerator Research Complex (J-PARC). This research was published in Journal of Materials Science and Technology.

This research was supported by the Ministry of Science, ICT, and Future Planning (MSIP) and the National Research Foundation of Korea.