Would there be any optical element that can eliminate the camera lens of the part of the smartphone which protrudes? The answer is yes. In 2019, the World Economic Forum, (WEF) has chosen metalens as one of the Top 10 future technologies. Metalens is a very thin and light planar optical device consisting of an array of nanostructure and has recently attracted so much attention that it is composed of a special issue in the world-renowned journal Nature Photonics. However, due to the necessity of precise technology and high-cost burden, making metalens is not simple.

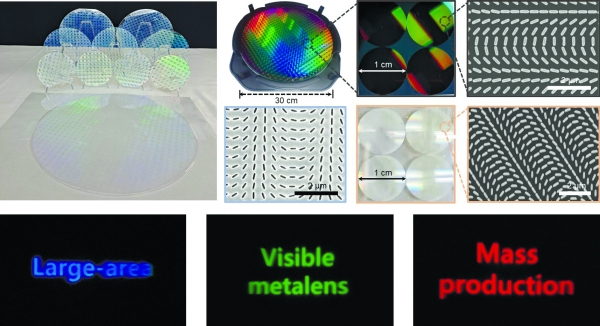

Recently, a research team led by Professor Junsuk Rho (ME, CE) succeeded in mass-producing visible band metalenses for the first time in the world with Korea University and Research Institute of Industrial Science & Technology (RIST). The study was published in Nature Materials, an influential journal in the field of materials.

The research team combined both technologies used in semiconductors and display manufacturing to overcome the limitations of the process. Photolithography is a combination of light and substrate printing, and it is a technology that engraves patterns on substrates like taking pictures using light.

The team first created a pattern with a high-speed electron beam and cloned the pattern with argon fluoride (ArF) photolithography to produce a 12-inch stamp. By using stamps and nanoimprint lithography, it succeeded in quickly printing metalenses with a diameter of 1 cm.

Traditional nanoimprint-based structures had a low refractive index and were very low in efficiency of around 10%, so it required a lot of money to increase efficiency. In order to improve the efficiency, the research team coated the printed lens with a very thin titanium dioxide (TiO2) film of about 20 nanometers (nm). Through the combination of the two technologies, it succeeded in mass-producing high-performance metalenses even with a simple process.

The research team then produced ultra-light virtual reality (VR) devices that can represent images of red, green, and blue, proving the practicality of meta-lens. Through the synergy between the two existing technologies, the commercialization of metalens has taken a step closer.

Prof. Rho said, “This study showed that metamaterial research, which has not been commercialized for 20 years, can be applied to the industrialization stage,” adding, “It is the world's first technology to mass-produce metalenses that can be used in visible light bands.”