Tactile sensors have been used as the basic platform of an artificial sensory system for fabricating robotic skins, prosthetics, haptic devices, and wearable or implantable devices. Several technological issues to produce practical tactile sensors have been intensively investigated and have seen remarkable advances. However, low power consumption and simple device structure are still big technological challenges. Among the potential power sources for tactile sensors, self-powered high potential signal generation with a weak external stimulus could be obtained through a triboelectric nanogenerator (TENGs), which creates electric signals from the small motion of human bodies.

Professor Kim Jin Kon of the department of Chemical Engineering (CE) and Director of the National Creative Research Initiative program for Smart Block Copolymers, Prof. Jeong Unyong (MSE), Jang Junho (CE Ph.D. candidate, advisor Prof. Kim Jin Kon), and Dr. Kim Dong Wook (MSE) have designed a self-powered, ‘one-terminal’ tactile sensor that can distinguish various motions on a single electrode . The research results were recently published in Nano Energy.

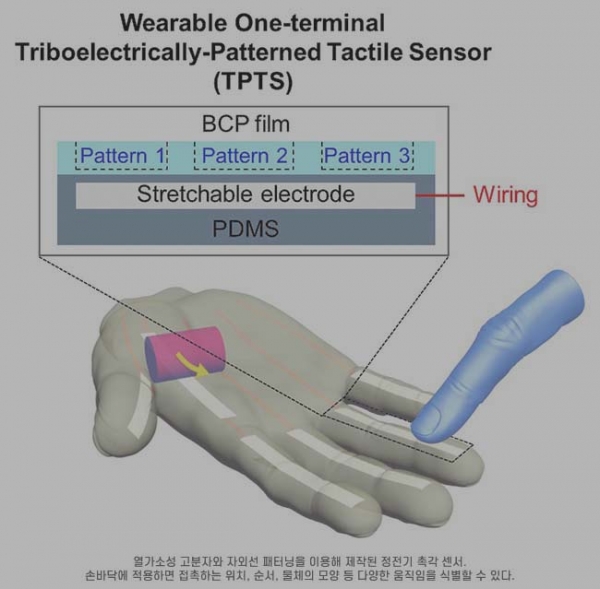

To fabricate their sensor, the researchers embedded a stretchable bottom electrode made of silver flakes in a thin polydimethylsiloxane (PDMS) substrate. Then they coated a thermoplastic block copolymers (BCPs) film on the substrate and irradiated it with UV light (254 nm) through a mask. Different times of UV irradiation were applied through the mask slits in order to control the triboelectric performance of the patterns. The space between the UV patterns played an important role as a potential barrier between the UV-irradiated area and the non-UV-irradiated area, which confined the triboelectric charges within the patterns by preventing the surface diffusion of the charges.

Using this design, the research team successfully fabricated a triboelectrically-patterned tactile sensor (TPTS) that generates various electrostatic signals through UV patterning with only one wiring on a single electrode. The patterns are made by UV irradiation on a thermoplastic BCP film. Only one signal terminal is used for TPTS, and dynamic touch motions can be captured when the TPTS is placed on a palm.

Prof. Kim Jin Kon says “We successfully fabricated a triboelectrically-patterned tactile sensor (TPTS) that generates various electrostatic signals through UV patterning with only one wiring on a single electrode”. He also says “Because this concept can simplify complex circuit design, it will greatly contribute to large-area tactile sensors or artificial skin in the future.”

This study was supported by the National Creativity Research Initiative Program funded by the National Research Foundation of Korea.