The resultant frictional electricity, which is spontaneously generated without external power, has stimulated active research across diverse fields. However, a prominent challenge lies in the limited sustainability of the charged electricity in sensors designed to detect static electricity.

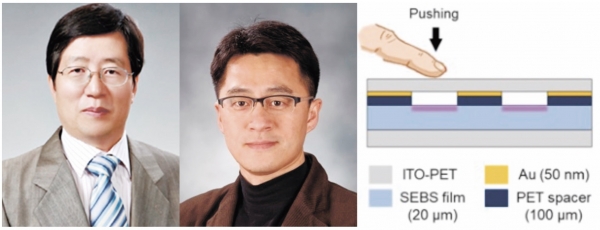

A collaborative research team from POSTECH, comprised of Professor Jin Kon Kim (CE), Dr. Junho Jang, Prof. Unyong Jeong (MSE), and Ph.D. candidate Woosung Cho, has recently published groundbreaking research in the international energy journal, Nano Energy. Their study focuses on overcoming the drawbacks of existing electrostatic sensors, which experience a gradual decrease in charged electricity over time and require repetitive contact and recharging processes.

Electrostatic sensors operate by converting the kinetic energy generated during friction between two different materials into electrical signals. Regarded as the next generation of power sources, these sensors have shown promise in various applications, ranging from electronic skin to medical sensors. In a previous study, the research team developed an electrostatic sensor capable of detecting multiple movements using a single electrode. However, a significant limitation arose as the charged electricity on the sensor diminished over time.

To address this issue and extend the duration for which the electrostatic sensor maintains its charged state, the research team introduced the concept of “Deep Traps.” These confined spaces within polymer substrate restrict the movement of surface charges. The team achieved this by exposing the sensor’s molecular materials to ultraviolet light, creating a chain structure, and forming the “Deep Traps” that successfully limit the movement of charges.

Furthermore, the researchers conducted experiments by applying a direct current (DC) voltage of 1,000 volts to the sensor, confirming a substantial improvement in electrostatic sustainability. The electrostatic sensor developed by the team demonstrated exceptional performance, maintaining its electrical charge for approximately 30 minutes. This represents a remarkable improvement, nearly 30 times longer than the typical one-minute duration observed in conventional electrostatic sensors.

Prof. Kim expressed his hope that this sensor, with its vast potential, would find diverse applications across various industries, effectively addressing the previous limitations of electrostatic sensors. The research signifies a significant stride toward advancing the capabilities of electrostatic sensors and their broader integration into real-world applications.

This study was conducted with the support of the Ministry of Science and ICT’s Creative Subsequent Research Project and the Mid-sized Researcher Support Project.