Michael Feygen is credited with developing the first 3D printer in 1985. 3D printing is known by many names depending upon the context: rapid prototyping, stereolighography, architectural modeling or additive manufacturing.

3D Printing is currently a hard term to define. Officially it is just one of the rapid manufacturing techniques. Currently however the term 3D Printing encompasses rapid manufacturing, digital manufacturing, direct digital manufacturing, rapid prototyping, desktop manufacturing, freeform fabrication, and fabbing. To sum up, 3D printing is a manufacturing process that builds layers to create a three-dimensional solid object from a digital model.

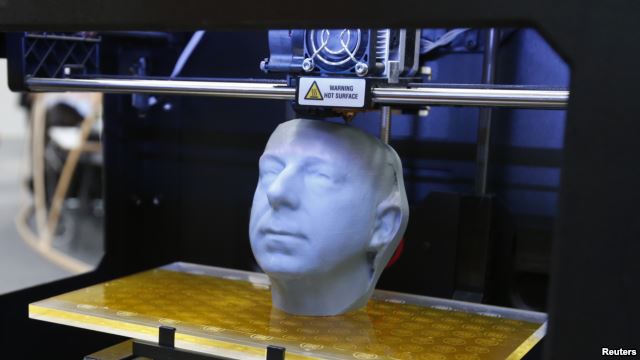

To print a 3D object, the manufacturer uses a 3D computer-aided design (CAD) program or animation modeling software to create a digital model that gets sliced into very thin cross-sections called layers. During the printing process, the machine reads the design from the file and lays down successive layers of liquid, powder, paper or sheet material to build the model from a series of cross sections. These layers, which correspond to the virtual cross sections from the CAD model, are joined or automatically fused to create the final shape. The primary advantage of this technique is its ability to create almost any shape or geometric feature. Though the printer-produced resolution is sufficient for many applications, printing a slightly oversized version of the desired object in standard resolution, and then removing material with a higher-resolution subtractive process can achieve greater precision. Some additive manufacturing techniques are capable of using multiple materials in the course of constructing parts. Some are able to print in multiple colors and color combinations simultaneously. Some also utilize supports when building. Supports are removable or dissolvable upon completion of the print, and are used to support overhanging features during construction.

In the past, the cost of 3D printing was expensive and the technology was only used by large corporations, but the development of desktop 3D printers has made the technology more accessible to small and mid-sized businesses and home users. Today, 3D printers are used to create anything from a new toy or motorcycle part to manufacturing prototypes for testing purposes. Before 3D printers existed, creating a prototype was time-consuming and expensive, requiring skilled craftsmen and specific machinery. Instead of sending modeling instructions to a production company, advancement in 3-D printing have allowed businesses to insource prototype production on a regular basis.

3D printing is mostly used in automobile, electric, and electronic businesses at present. If the price decreases significantly, it will bring about an innovation in the manufacturing process because it can print over 100 materials and does not need the frame for manufacturing. In the future, you will be able to create your own designs and 3D printers will print out the physical object for you.

ى €ى‘권ىگ © يڈ¬ي•ê³µëŒ€ى‹ 문 무단ى „ى¬ ë°ڈ ى¬ë°°يڈ¬ 금ى§€