Solid oxide fuel cells (SOFC) that use solid electrolytes are widely utilized in energy storage, transportation, and various applications. The efficiency of these cells depends on the performance and stability of the electrodes within the cell. To enhance this, the electrodes need to be manufactured with a porous structure, which means having pits in the cell wall. However, with current technology, coating ceramic materials uniformly on the porous electrode has been challenging.

Professor An Ji-hwan (ME) from POSTECH, and Prof. Jung WooChul (MSE) from KAIST, have successfully developed porous electrodes for SOFCs using advanced semiconductor processing techniques. This research has been recognized for its excellence and was recently published as a back cover article in the international materials science journal Small Methods.

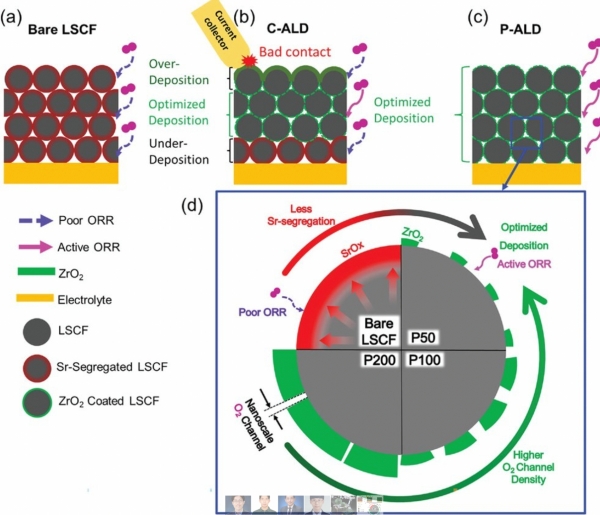

Previously, Prof. An’s team had improved the efficiency of SOFCs using atomic layer deposition(ALD) technology. ALD is a technique used to deposit materials in gas form onto a substrate surface in atomic layers uniformly. Here, they directly developed and applied a powder ALD process with equipment capable of precisely coating nano-thin films on fine powder surfaces.

Through this process, the research team uniformly coated zirconium oxide (ZrO2) ceramic material onto porous lanthanum strontium cobalt ferrite (LSCF) structures. Unlike conventional ALD processes for semiconductors, applying an atomic layer process to powder electrode materials enabled successful deposition throughout the structure. Experimental results showed that the electrodes produced by the research team increased 2.2 times, while the maximum power density of the cell and activation resistance of the cell efficiency decreased by 60%, compared to conventional methods.

Since powder ALD technology has high utility not only for SOFCs but also for hydrogen production and process-based technology, Prof. An stated “This is an example of innovation in the field of environmentally friendly energy systems”. He further expressed his ambition to improve sustainable environmentally friendly energy solutions through follow-up research.

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) along with Korea Energy Technology Evaluation and Planning (KETEP).