Plastic got its name—‘the present from god in the 20th century’—for its light weight, cheapness, and thermoplasticity. However, plastic transforms sensitively depending on the process condition. It also takes time to change a settled process. Hence, real-time optimization of plastic process was regarded as impossible.

The research team of Professor Junsuk Rho (ME and CE), Chihun Lee (ME Ph.D. Candidate, advisor Prof. Junsuk Rho), Prof. Seungchul Lee (ME), Juwon Na (ME Ph.D. Integrated Candidate, advisor Prof. Seungchul Lee), and Prof. Seongjin Park (ME) developed a system recommending the condition for the injection molding process, using artificial neural network and random searching. The research was published in Advanced Intelligent Systems.

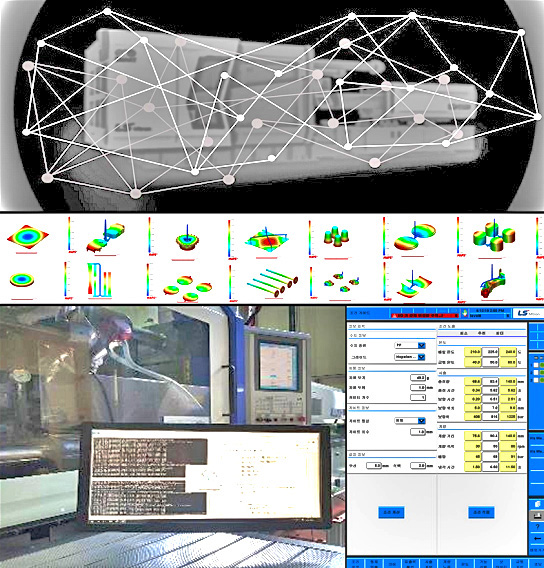

The research team studied the correlation between process condition and the final product by using Artificial Intelligence (A.I.). Three thousand six hundred simulation data and 476 experiment data produced from 36 molds were applied. As a result, each datum had five processes and 15 geometry features as input and one weight feature as output.

Also, based on the weight prediction model from transfer learning, they developed a recommendation system for optimized process conditions by random search. This way, they reached a mean relative error of 0.66%.

Finally, they developed a Graphic User Interface (GUI) for practical catapults. By entering the product’s shape information in this GUI, the error of resulting weights can be set under 1% easily.

Former studies only predicted the quality of the product by resetting the process condition of the previous product. However, in this research, the information of the product weight of all 36 shapes had been collected by differentiating conditions and shapes. Hence, if a new random product is shaped, the process condition can be controlled without further learning. Also, the quantity of simulation data and the precision of experimental data can be obtained by transfer learning.

This system is expected to be used in automated smart factories for various manufacturing, such as plastic ejection and cutting, 3D printing, and casting.

The research was conducted jointly with LS Mtron, the Korea Institute of Industrial Technology, VM Tech, and POSCO. The research was funded by the National Research Foundation of Korea and the Korea Evaluation Institute of Industrial Technology.