A research team led by Professor Rho Jun-suk (ME, CE) and Dr. Yoon Gwan-ho (ME) of POSTECH along with the research team of Professor Lee Heon (MSE) and researcher Kim Kwan (MSE) from Korea University have jointly developed a new nanomaterial and large-scale nano-printing technology for the commercialization of metamaterials. The research findings solve the issue of device size and high production costs that were problematic in previous research. The findings were recently published in Nature Communications, a prestigious scientific journal.

Metamaterials are substances made from artificial atoms that do not exist in nature, and they freely control the properties of light. Metamaterials can be used to make invisible cloaks that cause an illusion of disappearance by adjusting the refraction or diffraction of light or meta-holograms that can produce different hologram images depending on the direction of light’s entrance.

Using metamaterial’s attribute, the ultrathin meta-lens technology, which can replace the conventional optical system with extreme thinness, was recently selected as one of the top 10 emerging technologies to change the world in 2019 at the World Economic Forum.

To make metamaterials, artificial atoms smaller than the wavelengths of light must be meticulously constructed and arranged. Until now, metamaterials have been produced through a method called Electron Beam Lithography (EBL). However, EBL has hindered the commercialization or production of sizable metamaterials due to its slow process speed and high production cost.

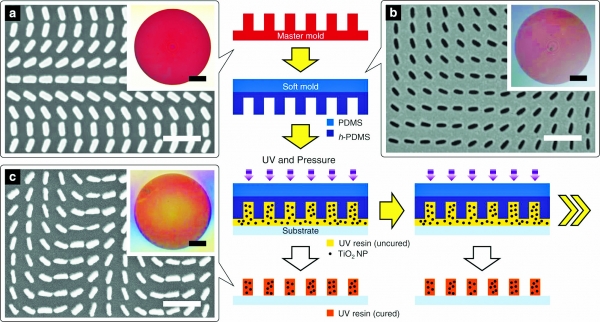

To overcome these limitations, the joint research team developed a new nanomaterial based on a nanoparticle composite that can be molded freely while having optical characteristics suitable for fabricating metamaterials. The team also succeeded in developing a one-step printing technique for shaping the materials.

The team succeeded in producing an ultrathin meta-lens that is 100 times thinner than a strand of human hair by using this newly developed technology. Metamaterials can now be made into 1/10,000 of the thickness of heavy glass or plastic lenses. This is the first time in the world such an ultrathin meta-lens was produced in a single-step printing process.

If the cost of making a meta-lens at the performance of conventional glass lenses were 10 million KRW per unit, this technology enables the production at about 10,000 KRW, which is 1/100 of the cost with the result of 1/10,000 the thickness in a simplified process.